Southwest’s largest ultrafine talcum powder project goes into production

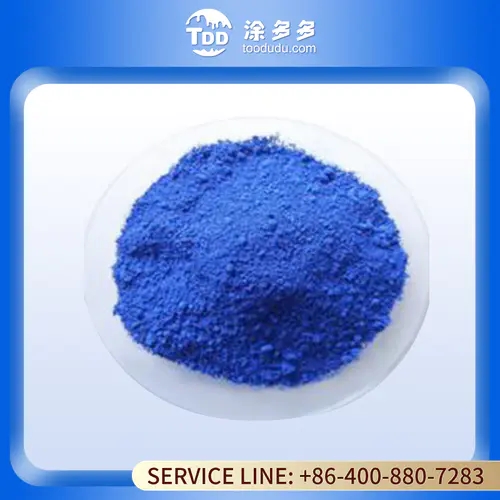

Mianning Xicheng Talc Mining Co., Ltd. is located in Mianning County, Liangshan Prefecture, Sichuan Province. It is the largest talc mining enterprise in southwest China. It took one year and invested nearly 400 million yuan. On the morning of the 13th, the ultrafine talc powder project with an annual output of 200,000 tons was officially completed and put into operation, marking a new path for the economic development of Liangshan Yi Autonomous Prefecture.

Mianning County is rich in talc resources. It not only has high whiteness, but also has huge reserves. The discovered talc reserves reach 4.5 million tons, making it the only large-scale talc mining area in southwest China. In recent years, Mianning County has made breakthroughs in economic development through the integration of rare earth and talc resources, and has successfully explored a new integration model for national economic development, that is, a mineral resource integration model involving "mineral rights as the core", which allocates superior resources to superior enterprises and promotes Industrial development, expand five major industrial clusters including rare earths, building materials, hydropower metallurgy, ferrous and non-ferrous metals, and processing of specialty agricultural and sideline products. In the first 11 months of this year alone, there were 36 industrial enterprises above designated size in the county, and the added value of industrial enterprises above designated size was 2.44 billion yuan, a record high. The county's economy and society have achieved sustainable, rapid and healthy development. The successful commissioning of the Xicheng Talc Mine’s ultra-fine talc powder project is a concentrated reflection of the county’s mineral resource integration achievements.

Zhou Xicheng, chairman of "Mianning Xicheng Talc Mining Co., Ltd." told reporters that superior resources should be allocated to superior enterprises. In order to establish an automated production line, the company invested 375 million yuan and finally realized green production. Next, the company will start the construction of plastic production lines in 2012 and invest 15 million yuan in high-tech research and development. In the future, the company will withdraw 10% of the total profits and taxes for high-tech research and development. By 2015, the company will continue to invest 200-300 million yuan to double its production capacity, and ultimately achieve sales revenue of 1.5 billion yuan and profits and taxes of 600 million yuan by 2016.

2024-01-22

2024-01-22  2024-01-31

2024-01-31  2024-01-31

2024-01-31  2024-03-10

2024-03-10  2024-01-23

2024-01-23